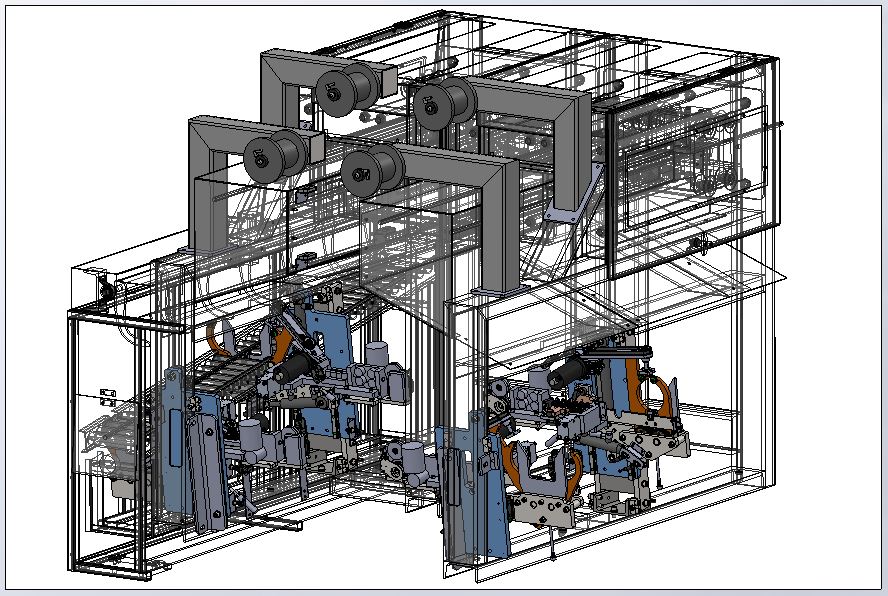

Start of the project of an automatic copper wire strapping machine for tying a package

Start of the project of an automatic copper wire strapping machine for tying a package

In response to customer demand for increasingly larger designed workstations, it’s time to expand our

The AMP design office begins work on a new device – matching feeders. It will come in 3 basic sizes. Versatility and adaptation to the needs of the market will make it an ideal and economical solution. The main advantage over conventional vibrating hoppers is very quiet operation, greater safety for the details being fed (no damage from aggressive vibrations), no need for additional controllers, precise dosing.